A lawn mower carburetor is a device that enables fuel to be released into the engine to keep it running. It’s an essential part of the lawn mower because it permits the fuel to mix with air to be burned to power the lawn mower engine. It is easy to identify them because they are usually placed near the engine and are typically bright red, green, yellow, or blue.

Carburetors are the heart of your lawn mower. They provide the fuel that allows your mower to run correctly. While there are different types of carburetors out there, it’s easy to determine the type you have based on where it is located on your mower.

Definition of Carburetor: What does carburetor mean?

A carburetor is a device for mixing air and fuel for an internal combustion engine. Carburetors are largely obsolete, having mainly been replaced by fuel injection systems in modern cars. However, they are still used in traditional vehicles, airplanes, marine engines, lawnmowers, and other mechanisms where simplicity and low cost are key factors.

Carburetors are used on gasoline, ethanol, biodiesel, kerosene, gaseous fuels, liquid fuels, and solid fuels. For example, the lawn mower carburetor is attached to the motor of a mower and is located underneath or behind the engine. The carburetor controls gas admission to the engine, which creates power. This allows the engine to adjust to different conditions.

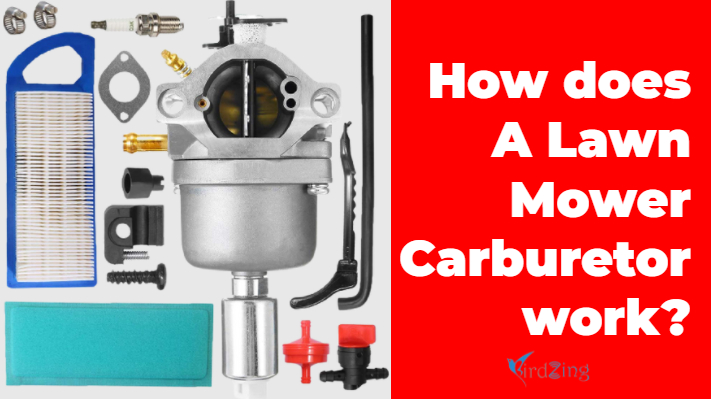

Parts of a Lawnmower carburetor:

To understand lawn mower carburetors, it helps to have a basic understanding of how they work. The main purpose of a carburetor is to mix the fuel with the air to burn efficiently. It contains many different parts, many of which are crucial to its proper functioning.

If you don’t know the parts, you won’t understand how to care for your new lawn mower. So let’s learn about the features so you can thoroughly clean your lawn mower carburetor.

Air filter:

The air filter of a lawn mower plays a vital role in ensuring that your lawn mower runs appropriately. The air filter keeps the air clean and clear of debris that could wear down the mower and reduces the risk of fire or explosion.

Float and the needle system’s function:

Understanding the purpose of the float and the needle system in a carburetor is critical to understanding how to troubleshoot a carburetor. The float system is responsible for adjusting the fuel level within the bowl as it fluctuates as a result of consumption as well as evaporation.

It’s also used to ensure that stale fuel is not being used and regulate proper ventilation of fuel from the bowl to the engine. When the fuel level reaches the set point, the float closes the wall and stops fuel from coming into the system.

Float chamber Section:

A float chamber is a part of a carburetor that measures the amount of fuel in a gas tank and sends it to the engine. Float chambers are four parts: a float bowl, a float rod, a venturi assembly, and a rich mixture needle.

All float chambers have vents. The vents maintain a neutral atmospheric pressure by releasing gas from the chamber. It is shown that float chambers with vents will maintain an accurate reading. This is because atmospheric pressure exists on both sides of the chamber, and because atmospheric pressure is lower on the upstream side.

Venturi:

The venturi is a crucial part of your lawn mower carburetor. The venturi is a cone-shaped passage that is located in the throat of the carburetor. It controls the flow of air and fuel as it passes through the carburetor. To function correctly, the venturi must be clean.

A venturi tube is a tube that is constricted at one end and opens on the other. Since a venturi is almost always used in fluid dynamics, we will focus on how it relates to lawn mower carburetors. You do not need to worry too much about the venturi effect if you have a lawn mower with an utterly functional carburetor.

The flow of air through the venturi slows down through the throat of the tube but is increased in speed on the other side. This is because the pressure created on the other side is greater than the pressure inside the float chamber. However, this pressure is not enough to generate torque on the floats, so it stays put.

A metering system is put in place to regulate the fuel’s release. The fuel is then pushed through a throat that creates a vacuum-like force. This is what breaks the fuel into a uniform mix with air, which in turn makes it easier for it to produce a clear-enough flame.

Throttle valve:

The throttle valve is the device that allows the engine to deliver fuel at the desired speed. The throttle valve is controlled by hand or automatically, depending on the type of mower you have. A manual-throttle mower uses a lever that’s attached to the handlebar to control the speed of the engine.

Choke wall:

The choke wall (also known as the throttle wall or throttle disc) is a small piece of steel engine’s speed round in most gas lawnmowers. The choke wall sits between the throttle and the carburetor and is attached to the throttle cable. The choke wall has an essential role in helping to regulate the speed of your lawn mower engine, and you should not overlook any issues that arise with this tiny piece of steel.

How does a lawn mower carburetor work?

When it comes to small engines and lawn equipment maintenance, the carburetor is essential. The carburetor regulates gas and air mixture and determines whether the engine runs at its best. Cleanliness and tuning of the carburetor are crucial. In addition, machine making depends on it. This is important for everyone, so read carefully about how a carburetor works and how you can take care of it.

- Air and gas are mixed to create a charge fed into an engine’s cylinder.

- Carburetor depression occurs when the air pressure in the float chamber is less than the pressure at the throat of the venturi.

- Keep the fuel level in the float chamber below the tank’s nozzle for safety and optimal performance.

- Gasoline engines need to be adjusted for power output. They do this by delivering a charge to the engine cylinder for different lengths of time.

- If the throttle is closed, airflow through the venturi will not flow. As a result, the idle air bleed is required to supply enough fuel and air mixture. Idling means keeping the engine running when the vehicle is not in motion.

- When the throttle has a partial opening, not enough air will flow through the venturi, which means that there is less pressure drop and this, in turn, means that less fuel will be discharged through the discharge nozzle. Therefore, the air/fuel mixer will produce less fuel for the engine cylinders. As a result, power output will be reduced.

- When the throttle is fully open, the pressurized air in the exhaust will flow through the vents in the carburetor. This causes more fuel to be released into the cylinder. Therefore, more air and fuel are consumed, which generates more power to be produced.

- A choke wall is a mechanical device that is used to restrict or throttle the passage of air. It helps us in winter to start the engine.

When should it be serviced?

Lawn mower carburetors should be serviced every year or two, depending on how often the engine is used. Regarding lawnmowers, carburetors are one of the most important parts, and they can easily malfunction if not tended to.

There are a few things that you should keep in mind when servicing a lawn mower carburetor:

- Check the air filter. If it’s dirty or clogged, this will prevent the engine from breathing properly and could result in problems with the carburetor.

- Check the fuel level and ensure it is enough for the mower to run correctly. Overfilling can cause bubbles in the gasoline mixture that can damage the carburetor.

- Make sure there are no buildups of gas or oil on any part of the carburetor – this will also lead to problems with ignition and gas flow.

How to replace the Lawn Mower Carburetor?

If your lawn mower is not starting, has low power, or makes strange noises, it may be due to a carburetor issue. Here’s how to replace the Lawn Mower Carburetor:

- Remove the spark plug. It’s typically located near the engine.

- remove the air cleaner by unscrewing it and pulling it out of the way. It may have a hose attached that you can use to help clean out any debris inside the carburetor.

- Remove the screws that hold onto the carburetor body and slide them off the engine mountings.

- Carefully remove the old carburetor assembly and replace it with a new one. Be sure to tighten all of the screws in place before replacing the air cleaner and spark plug!

Carburetor Troubleshooting tips

If you’re having problems with your lawn mower carburetor, there are a few things you can do to try and fix the problem.

- Check the fuel level. Make sure that the fuel tank is complete before starting the engine. If it’s not, then add some gasoline to the tank.

- Check the air filter. If it’s clogged or dirty, it may be causing problems with the lawn mower carburetor. Remove the air filter and clean it using a vacuum or a duster before reinstalling it.

- Add more air if needed. If the lawn mover isn’t getting enough air into its carburetor, you may need to open up the throttle slightly to give it more airflow. Just be careful not to overdo it – too much air can lead to engine damage!

- Adjust the choke cable if needed. A properly adjusted choke cable will help improve engine performance by preventing unnecessary smoke and heat from entering the carburetor.

Tuning Process

The carburetor must be tuned if your lawnmower is not cutting evenly or the engine seems weak. Follow these simple steps to tune a lawn mower carburetor:

- Park the lawnmower in a safe place where you can safely work on it.

- Disconnect the spark plug wire from the spark plug.

- Open the air filter cover and remove the air filter.

- Check that all the screws securing the carburetor are tight and that no debris is blocking them (carburetor floats should move freely when you shake them).

- If necessary, remove debris from the float bowl using a vacuum cleaner and a q-tip soaked in gasoline or kerosene oil.

- Replace any blocking particles with new gaskets supplied with your carburetor or use gaskets from an old carburetor that you’re willing to disassemble (see the Resources section at the end of this article for more information).

- Reinstall all screws and replace the air filter cover.

Final Words:

Lawn mower carburetor statistics from the U.S. Department of Energy reveal that gasoline engines account for more than 15 percent of all carbon monoxide emissions in the United States. The U.S. Environmental Protection Agency has set a goal to reduce U.S. greenhouse gas emissions by 3 percent of their 2005 levels by 2020. And if you’re a homeowner with a yard, you’ll likely have a gas-powered lawn mower.

In the world of lawnmowers, carburetors have been in use for a long time. They have been around since the early days of the mid-1800s. They have evolved a lot in that time, though. As a result, carburetors in today’s mower engines are a bit more sophisticated than they used to be.

I love gardening and hope you enjoy reading my post as much as I enjoy writing it. I focus on plant-based living and believe that you will be healthier and happier by incorporating more plant-based foods into your diet. By providing helpful tips and advice on everything from garden design to growing techniques, I want to help make gardening easier for everyone.

Pingback: 10 Tips You Need To Know About Converting Lawnmower Motor Into Boat Motor: A Complete Video Guide